In recent years, 3D printing has taken the world by storm. Technology has been used to create everything from prosthetic body parts to cars.

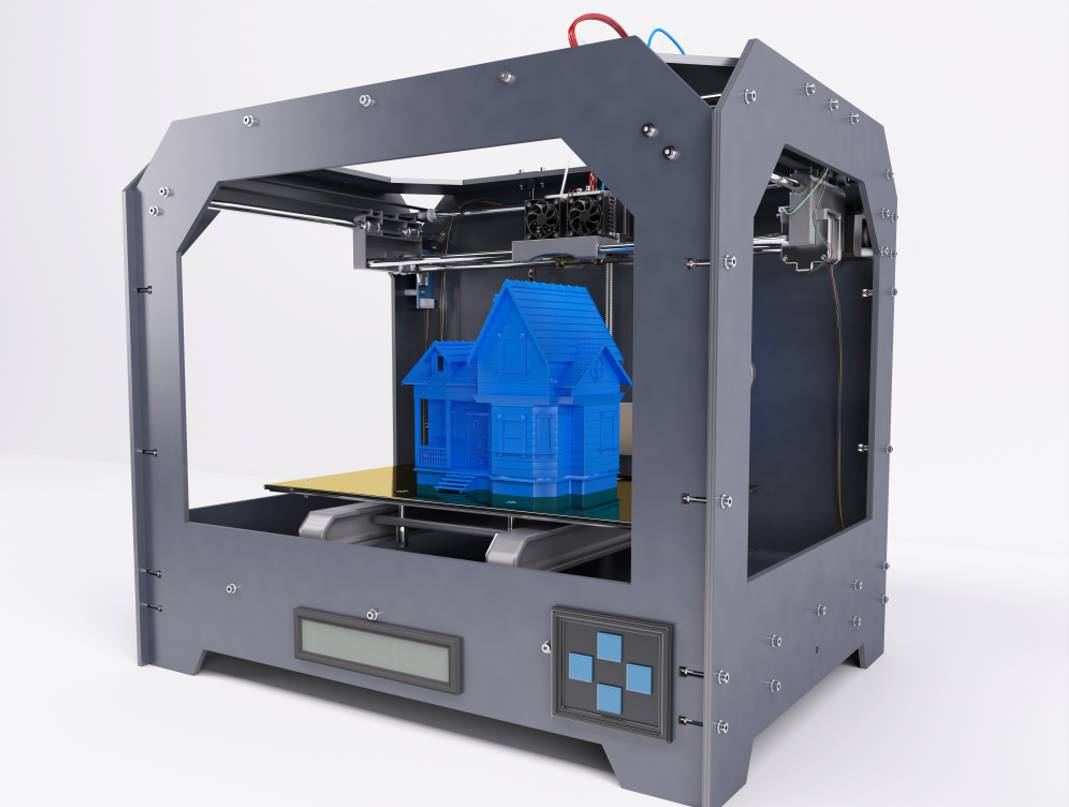

Now, a new application of 3D printing is emerging: the construction of houses. 3D-printed homes are created by printing layers of material to form the walls, roof, and other structures of a house. This technology is still in its early stages, but it has the potential to revolutionize the construction industry.

Here are several things to know about them and how you can build one too.

How do 3D-printed houses work?

3D-printed homes are created by printing layers of material to form the walls, roof, and other structures of a house. This works by using a large 3D printer to print the layers of material one on top of the other. The machine can print homes of any size and shape, making it very versatile.

For instance, to build house walls, the printer would lay down layers of material until the desired thickness is reached. The same process would be used for the roof and other parts of the house. Once all the parts are printed, they would be assembled like a jigsaw puzzle to form the complete structure.

What materials can be used to print 3D houses?

A variety of materials can be used to print 3D houses, including concrete, plastic, and metal, however, the most commonly used material is concrete. This is because it is strong and durable, making it ideal for construction purposes. To work with other materials, such as metal, you would need a factory or agency that offers a 3D metal printing service because these elements require different temperatures and processes to be used. Special machines would also be needed to print with these materials.

On the other hand, if you want to use plastic, it would be easier because you can purchase a 3D printer that works with this material. The price of the machine would be lower than those used to print with metal or concrete.

3D-printed houses are affordable

These homes could be very affordable as technology develops and becomes more widespread. Additionally, they can be built quickly and easily, without the need for heavy machinery or a large team of workers. This makes them ideal for emergencies, such as natural disasters, where shelter is urgently needed. Their affordability will also help to reduce homelessness, as these homes can be built for a fraction of the cost of traditional houses.

However, it should be noted that 3D-printed homes are not yet widely available, and they are currently only being used by a small number of people, usually those with access to expensive 3D printers. This dictates that, for the time being, 3D-printed houses are not suitable for mass production.

3D-printed homes are environmentally friendly

3D-printed homes are very environmentally friendly as they produce little or no waste. The construction process is also very efficient, using less energy and resources than traditional methods. Additionally, these homes can be made from recycled materials, further reducing their impact on the environment.

As 3D-printed homes become more popular, their environmental benefits will likely increase as well. This is because more people will be using them and companies will be searching for ways to reduce their environmental impact even further.

They are strong and durable

3D-printed homes are just as strong and durable as traditional houses. This is because the materials used to print them are the same as those used in conventional construction. Additionally, 3D-printed homes can be designed to withstand extreme weather conditions, such as hurricanes and earthquakes.

This makes them ideal for use in disaster-prone areas, as they can provide much-needed shelter in the event of a natural disaster.

On the other hand, traditional houses usually need to be built close to where they will be used, as they need to be transported there. This can be difficult, especially if the location is remote or difficult to access. However, 3D-printed homes can be transported to any location, no matter how remote, and then assembled on-site.

This makes them ideal for use in remote locations, such as the mountains or the desert, as they can be easily transported there and assembled with minimal effort.

3D-printed homes can be customized

Another benefit of 3D-printed homes is that they can be very customizable. This means that you could have a home that is designed specifically to meet your needs and preferences. For example, if you wanted a house with large windows to let in lots of light, this could easily be incorporated into the design.

Additionally, if you have a disability, such as a wheelchair user, the house could be designed to make your life easier by incorporating features such as ramps and wider doorways.

However, it should be noted that customization can also add to the cost of a 3D-printed house.

Who can make a 3D-printed house?

3D-printed homes can be made by anyone with access to a 3D printer. However, it should be noted that the price of these printers can vary greatly, with some being very expensive, depending on their size, the material they work with, and their features. Additionally, the software required to design a 3D-printed house can also be costly.

Therefore, you would need to invest a significant amount of money to be able to make your own 3D-printed house.

However, if you cannot afford to buy a 3D printer or the software required, you could always use a 3D-printing service. These services usually work by allowing you to upload your design, and then they will print it for you. Depending on the size and complexity of your design, the price of this service can vary, but it is generally cheaper to build a 3D-printed house than a traditional one.

3D-printed homes are still in their early stages of development and there is much room for improvement. Additionally, the technology is still quite expensive, which limits its use to those who can afford it.

However, as technology develops, 3D-printed homes will likely become more affordable and widely available. This is good not only for the environment, but also for those who want to have a more customized and unique home.