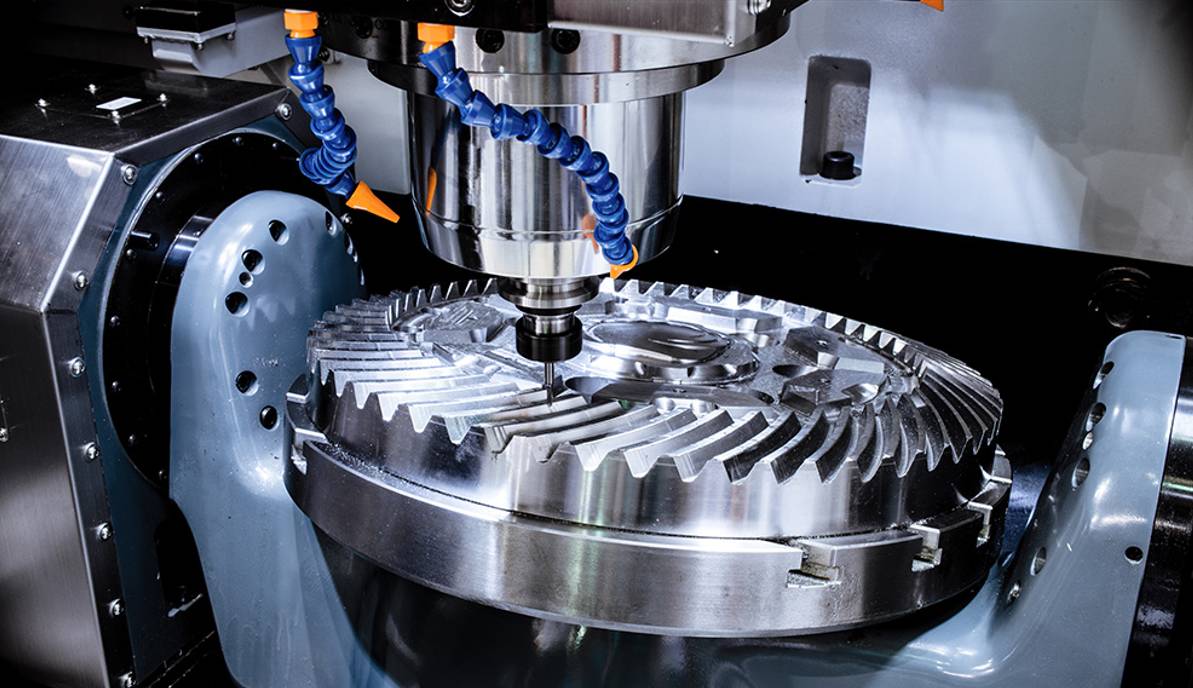

Look into CNC machining, and a layperson could easily get confused trying to figure out what the differences are between the various options for metal work. While it is true that the more axes involved with a CNC lathe system provides more detail and intricacy, that doesn’t automatically translate to the greater axes number being the best choice for a particular job. The difference and choice depend on the part design, how it will be used, the material and the scale and scope of the project. All of these factors can influence whether one type of axis is better than the other. There is no default, automatic-best choice in most cases. Here’s why below.

Technically speaking, the big differences between the lower end of a 3-axis CNC lathe and the upper end of the 5-axis choice as well as the 4-axis system, comes with the additional positions and angles available to the machine and programming. Generally, the CNC lathe works by moving tools into position on the item to do the necessary work. These positions start off with a basic three-point location approach. From there, additional factors can be added, such as rotation and angle, which create more location possibilities depending on where the target material is compared to the position of the tooling involved.

The 3-axis CNC machine approaches shaping of a part from three directions. Up-down, left-right, and forward-backward. Given that a CNC lathe is focused on the shaping of a part that is circular, the tooling contacts are moved around the part. That target remains stationary and locked. The movement is entirely controlled by the machine and driven by the directions fed into it through programming. This approach works extremely fast with simple designs, and 3-axis lathe work is typically applied to produce parts with high durability, long-lasting performance, but low on the detailed quality score or intricate work. 3-axis work is extremely useful for repetitive work involving edging, cutting, drilling, slotting and similar. It can work around the target material in different patterns and directions, producing a very functional end product in a short amount of time by removing material to produce the desired part shape.

The disadvantage of a 3-axis lathe is that it can only approach the part with the original 3-location combination that it was programmed with. This becomes a limitation when the same work needs to be applied from a different angle. Since the tooling cannot achieve these changes, the part has to be re-positioned and new programming applied. This requires another cycle of design, programming, setup and application. For complex parts, multiple setups can be required to finish one part completely. It becomes cumbersome and long in duration from beginning to end.

The 4-axis CNC machine adds one more layer of position by rotating the target material. Rather than being fixed, it moves in a spinning, rotating fashion, which can be continuous, or it can be intermittent. The same three tooling positions of the 3-axis apply, but now the target can be rotated as well. This cuts down on the work that otherwise would have been required to reposition the target material in a rotational fashion. Instead, the part can be spun as needed, both continuously or in a locked, periodic fashion of move, lock, work, move, lock and work. A good example of a 4-axis approach would be the fabrication of a camshaft singular unit for a vehicle engine. All of the various edges and parts of the camshaft could be designed and shaped with the 4-axis application, and the camshaft piece resource could be rotated as needed for each step of the work.

Again, while an improvement over the 3-axis lathe, the 4-axis CNC lathe still doesn’t have the ability to change angles of rotation. It rotates in a fixed fashion, which in turn also requires additional setups for changes in angle of the rotation as well as the other applications.

The 5-axis CNC lathe machine solves the missing element of the above two systems. 5-axis CNC machining provides the ability to change the angle of the vertical or horizontal, creating far more capability. At the same time, it still incorporates all the elements of vertical, horizontal, depth and rotation. What was limited to just a vertical rotation or horizontal rotation can now be pivoted 360 degrees as needed and worked on at the same time. The capabilities of this level of a lathe are exponential as a result.

The 5-axis approach comes either in a continuous operating system or an index or periodic stop design. The fully continuous system is ideal for products that are to be created on two different rotational paths. The alternative 3+2 system is ideal for unique and specific three-dimensional products that would otherwise have been crafted manually or by mold.